Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Ever wondered how plastic products are made? Extrusion machines play a key role. They transform raw materials into finished items efficiently. An extrusion line is a series of machines that melt and shape plastics. These lines are crucial in manufacturing, producing pipes, sheets, and more. In this post, you'll learn about extrusion lines and their costs, helping you make informed decisions for your business.

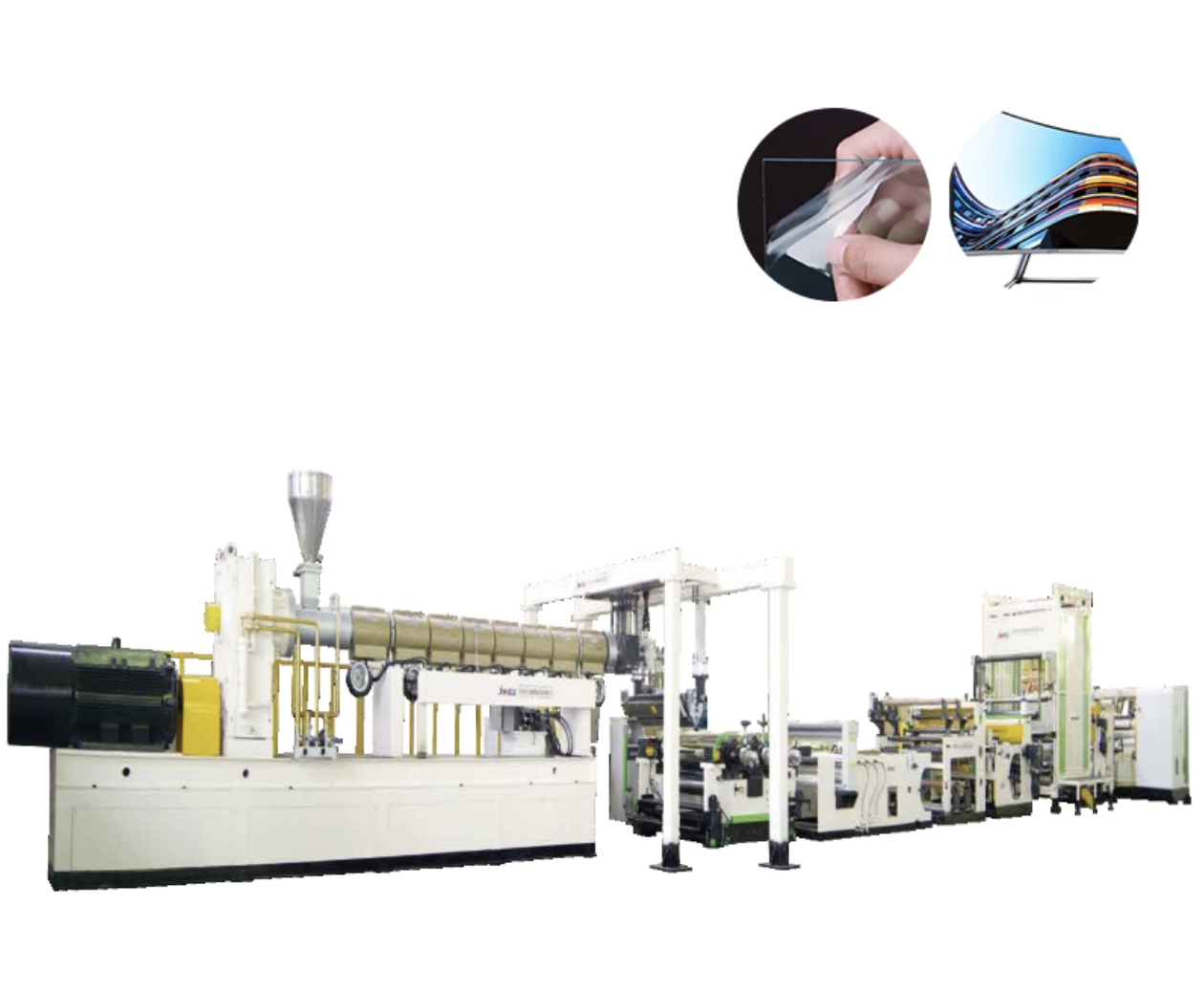

Investing in an extrusion line is a significant decision for any manufacturer. An extrusion machine transforms raw plastic or composite materials into pipes, sheets, profiles, or films, providing high-volume, consistent production. However, understanding the cost involved is crucial for effective budgeting and ROI planning. The cost of an extrusion line varies greatly based on machine type, material compatibility, production capacity, automation level, and downstream equipment. In this article, we explore all factors that influence extrusion line pricing, helping businesses make informed investment decisions while optimizing efficiency and output quality.

An extrusion machine is industrial equipment designed to melt and shape raw plastic into continuous products. The process begins with loading plastic pellets or powders into a hopper, which feeds the material into a heated barrel. Inside the barrel, a screw pushes the material forward while heating and mixing it to create a uniform melt. The molten plastic passes through a die, forming the desired profile, whether it is a pipe, sheet, or custom profile.

Modern extrusion lines include multiple integrated systems, such as cooling tanks, haul-offs, cutters, and multi-layer die heads. These components allow for consistent production and precise product dimensions but also contribute to the overall cost of the extrusion machine. Additionally, the choice between single-screw and twin-screw extruders affects both initial investment and long-term operational efficiency.

Extrusion machines provide unmatched efficiency and scalability. Continuous operation allows manufacturers to produce large volumes of uniform products without frequent downtime. Unlike batch processes, extrusion minimizes material waste and reduces labor costs.

Choosing the right extrusion machine ensures that project specifications, such as pipe diameter, profile complexity, or sheet thickness, are met consistently. For example, multi-layer pipe extrusion lines can produce layers with specific properties, such as corrosion resistance or oxygen barriers, which adds value but increases machine cost.

Extrusion machines also allow manufacturers to experiment with new materials, including recycled plastics or composite blends, enhancing sustainability and broadening product offerings.

The screw and barrel are the heart of an extrusion machine. The screw moves, compresses, and melts material while ensuring proper mixing and temperature control. Twin-screw extruders excel at processing abrasive or complex materials like wood-plastic composites (WPC), PVC blends, and filled polymers. Single-screw extruders are more cost-effective for simple thermoplastics such as polyethylene (PE) or polypropylene (PP).

Proper screw selection affects not only the machine cost but also throughput, energy consumption, and melt quality. Modern extruders include segmented screws with adjustable elements, allowing fine-tuning for specific materials and improving long-term efficiency.

Die heads are precision tools that determine the product's final shape. Multi-layer dies or spider dies increase upfront cost but allow production of sophisticated pipes, profiles, or films with multiple functionalities. Tooling also includes calibrators, cooling systems, haul-offs, and cutting units, all of which ensure consistent dimensions and reduce waste.

Investment in high-quality dies and tooling pays off through fewer defects, reduced scrap, and enhanced product reliability.

After extrusion, products require precise cooling, hauling, and cutting. Cooling systems, whether water tanks, chill rolls, or air cooling, stabilize shape and prevent warping. Haul-off units control speed and tension, while cutters, winders, or stackers finish the product. Automated quality control systems, such as laser thickness sensors or inline cameras, help maintain dimensional consistency.

Tip: Advanced downstream automation increases initial extrusion line cost but significantly reduces labor expenses and waste over the long term.

Extrusion lines serve multiple industries due to their versatility:

● Construction: PVC, PE, and PP pipes for plumbing, sewage, gas, and electrical conduits. Profile lines produce window and door frames, vinyl siding, and architectural trims. Sheet lines create roofing panels or insulation boards.

● Packaging: Extruded sheets, films, and thermoformed trays or cups. Blown film lines produce bags, agricultural films, and stretch wraps.

● Automotive: Flexible PVC tubing, gaskets, seals, dashboard trims, and protective sleeves. Extrusion reduces vehicle weight by replacing metal parts with durable plastics.

● Consumer Goods and Furniture: Foam boards, tubing, furniture trims, and vinyl flooring. WPC extrusion lines produce decking, fencing, and decorative profiles.

Each application requires specific extrusion machine configurations, which directly influence the cost. Multi-layer pipe lines or WPC lines are more expensive than simple single-screw PE pipe lines due to complexity and additional tooling.

Tip: Selecting an extrusion line tailored to your industry ensures that initial investment aligns with expected production outcomes and product quality standards.

An extrusion line consists of several critical components working together to transform raw plastic into finished products. Each part plays a vital role in ensuring the process runs smoothly and produces quality output. Let’s explore these key components:

The extruder is the heart of the line. It melts and pushes plastic through the system. Typically, it includes a motor-driven screw inside a heated barrel. As the screw turns, it moves plastic pellets forward, melting and mixing them into a uniform molten state. There are two main types:

● Single-screw extruders: Common for simpler materials like polyethylene or polypropylene. They are cost-effective and reliable for many applications.

● Twin-screw extruders: Often used for more complex materials like PVC or wood-plastic composites (WPC). They provide better mixing and temperature control, improving product consistency.

The extruder's design, including screw shape and barrel quality, directly affects efficiency and product quality.

At the extruder’s end, the die shapes molten plastic into the desired profile. Dies are precision metal tools custom-made for each product’s cross-section—pipes, sheets, profiles, or foam boards. Alongside dies, calibrators or form inserts may be used immediately downstream to maintain exact dimensions while the plastic cools.

For complex shapes or hollow profiles, vacuum calibrators are common. They help the soft extrudate retain its shape by cooling it under slight vacuum pressure. High-quality tooling is essential for smooth surfaces and tight tolerances.

Once shaped, the hot plastic must cool quickly to solidify and keep its form. Cooling systems vary depending on the product type:

● Water baths or spray tanks: Common for pipes and profiles, gently cooling the material as it moves through.

● Cooling rolls or conveyor belts: Used for flat sheets or films, pressing and chilling the extrudate to precise thickness.

Proper cooling prevents warping and ensures dimensional accuracy.

The haul-off unit pulls the extruded product steadily through the line. It uses belts, caterpillar tracks, or rollers to grip the material without stretching or deforming it. Synchronizing haul-off speed with extruder output is crucial for consistent thickness and shape. This component keeps the process continuous and smooth.

Finally, the continuous extruded product must be cut or coiled for handling and packaging. Cutting units chop pipes or profiles into lengths, while winding machines roll sheets or films into coils. The choice depends on the product type and downstream requirements.

Tip: Regular maintenance of key components like the extruder screw, die, and haul-off ensures consistent product quality and minimizes costly downtime.

Extrusion lines offer many benefits that make them a popular choice for manufacturing plastic products. These advantages help businesses produce high-quality items efficiently and cost-effectively.

Extrusion lines operate continuously, allowing nonstop production. Once running, they can produce large volumes of product without frequent stops. This steady operation reduces downtime and labor needs. For example, a pipe extrusion line can run 24/7, producing hundreds of meters daily. This efficiency lowers the cost per unit and meets high demand easily.

Because extrusion is a continuous process, it produces uniform products with consistent shapes and dimensions. Precise control over temperature, pressure, and line speed ensures every piece meets specifications. Automated sensors and feedback systems help maintain tight tolerances. This consistency reduces waste and scrap, saving money and time.

Extrusion lines can create a vast range of profiles, from simple tubes to complex window frames. Changing the die and calibrators allows quick switching between products. Manufacturers can produce custom shapes without needing new machinery. This flexibility supports diverse product lines and fast response to market needs.

Extrusion generates little waste. Scrap from trimming or off-cuts can often be recycled back into production. Continuous operation avoids startup losses common in batch processes. Lines can also co-extrude layers, blending recycled or lower-cost materials inside products without sacrificing quality. This efficient use of materials reduces overall production costs.

Tip: Regularly calibrate sensors and maintain cooling systems to sustain product quality and maximize extrusion line efficiency.

The choice of material impacts extruder type, screw design, and heating profiles. PVC and WPC often require twin-screw extruders for thorough mixing, while PE and PP can use single-screw extruders. Recycled materials may require vented extruders to remove moisture and contaminants.

Consider the daily or hourly output you require. Larger machines with bigger screws increase upfront cost but lower the per-unit production cost over time. Modular designs allow scalability without full replacement, providing a flexible path for growth.

Modern extrusion lines offer advanced automation, including gravimetric feeders, automatic thickness controls, and real-time quality monitoring. These features raise initial extrusion line price but reduce labor needs, improve safety, and ensure consistent product quality.

Energy-efficient motors, heaters, and drives reduce long-term operational costs. Investing in energy-saving features might increase initial extrusion machine cost but ensures sustainable operation and lower electricity bills.

Tip: Always evaluate material, throughput, automation, and energy efficiency together to select an extrusion line that optimizes both investment and operational costs.

The total cost of an extrusion line is influenced by multiple factors:

● Extruder Type: Single-screw vs. twin-screw. Twin-screw extruders are more expensive but necessary for complex or abrasive materials.

● Number of Layers: Multi-layer lines increase tooling and calibration complexity.

● Downstream Automation: Haul-offs, cutters, and scanning systems add cost but reduce labor and waste.

● Material Complexity: Specialty polymers, composites, or recycled materials may require specialized screws and dies.

● Energy-Saving Features: Advanced drives, heaters, and control systems increase initial investment but reduce operating costs.

Factor | Cost Impact |

Single vs Twin Screw | Medium-High |

Multi-layer Dies | High |

Downstream Automation | Medium-High |

Material Complexity | Medium |

Energy-Efficient Features | Medium |

Tip: Higher initial investment can reduce long-term costs by improving efficiency, minimizing scrap, and enhancing product quality.

Understanding extrusion line cost is not just about upfront price. Total cost of ownership includes energy, maintenance, labor, raw materials, and potential scrap.

● Energy Costs: Machines with optimized heaters and smart drives consume less electricity.

● Labor: Automated systems reduce the need for operators and improve consistency.

● Material Efficiency: High-quality dies and screws minimize rejects.

● Maintenance: High-end machines may require less frequent maintenance, reducing downtime.

By analyzing these factors, manufacturers can estimate payback periods and return on investment, ensuring extrusion line purchases support long-term profitability.

Tip: Consider total cost of ownership, including operational and maintenance expenses, to make informed extrusion line investments.

Understanding the factors influencing extrusion line costs is crucial for making informed investment decisions. Material type, production capacity, and quality needs significantly impact initial and operational expenses. Choosing the right extrusion line ensures efficiency and product quality. For businesses seeking reliable solutions, Foshan Bkwell Machinery Co., Ltd. offers advanced extrusion lines tailored to specific needs, providing excellent value through high-quality components and robust support services. Investing wisely in these systems can enhance production capabilities and long-term profitability.

A: The cost of an extrusion machine is influenced by material compatibility, production capacity, quality requirements, and automation level. Different materials and high-capacity needs can increase complexity and price.

A: Higher production capacity requires larger extrusion machines with powerful motors and advanced control systems, leading to increased upfront costs but potentially lower per-unit production costs.

A: Twin-screw extrusion machines offer better mixing and temperature control, making them ideal for complex materials like PVC or wood-plastic composites, though they often cost more than single-screw models.