Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Imagine transforming raw plastic into versatile products with precision. That's the power of an extrusion machine. These machines revolutionize manufacturing by efficiently producing uniform plastic components. In this post, you'll learn how extrusion lines operate, their key components, and the diverse applications they serve across industries. Discover why extrusion lines are essential for modern manufacturing success.

An extrusion machine is a specialized device that melts raw plastic material and shapes it into continuous profiles. It works by heating plastic pellets or powder until molten, then pushing this melted plastic through a custom-shaped opening called a die. The die determines the final product’s cross-sectional shape, whether it’s a pipe, sheet, profile, or tube. Because the process runs continuously, extrusion machines are ideal for producing long lengths or large quantities of uniform plastic products efficiently.

In simple terms, the extrusion machine acts like a giant syringe that melts and forces plastic through a mold. Once the plastic exits the die, it cools and solidifies, retaining the shape formed by the die. This continuous operation allows manufacturers to produce consistent, high-volume plastic components for many industries.

Extrusion machines consist of several critical parts that work together to melt, shape, and cool plastic material:

● Hopper: This is the entry point where raw plastic material is loaded. It feeds pellets or powder into the machine.

● Screw and Barrel: Inside the barrel, a rotating screw pushes plastic forward while heating it. The barrel has heating zones controlled to maintain the right melt temperature. The screw design (single or twin-screw) affects mixing quality and output.

● Die: Attached at the barrel’s end, the die shapes the molten plastic into the desired profile. Dies are precision tools customized for each product shape.

● Cooling System: After leaving the die, the hot plastic passes through cooling tanks or rolls to solidify and maintain its shape. Cooling prevents warping and ensures dimensional accuracy.

● Puller (Haul-off): This mechanism pulls the extruded plastic steadily through the cooling area, controlling speed and preventing distortion.

● Cutting or Winding Equipment: Depending on the product, the continuous plastic is cut to length or wound into coils for further handling.

Each component must be carefully calibrated and synchronized. For example, the screw speed must match the puller speed to keep product dimensions consistent. Modern extrusion machines often include sensors and automated controls to maintain precise temperatures, pressures, and speeds, ensuring high-quality output with minimal waste.

The choice between a single-screw and twin-screw extruder depends on the material and product requirements. Twin-screw extruders offer better mixing and are common for complex materials like PVC or wood-plastic composites. Single-screw extruders are simpler and used for many polyolefin products like polyethylene.

Understanding these components helps manufacturers optimize extrusion performance, reduce downtime, and produce products meeting exact specifications.

Tip: When selecting an extrusion machine, consider the screw type and die design carefully, as they directly impact melt quality and final product consistency.

The extrusion process turns raw plastic into shaped products by melting and pushing it through a die. It starts when plastic pellets or powder enter the extruder’s hopper. Inside the heated barrel, a rotating screw pushes the plastic forward. Heat and friction melt the plastic into a thick, flowable state called the melt.

This molten plastic is forced through a die—a metal tool shaped like the final product’s cross-section. As the plastic passes through, it takes on this shape, forming a continuous profile. The extruded material then moves through cooling systems like water baths or chilled rollers. Cooling solidifies the shape quickly to keep it from deforming.

Finally, a haul-off unit pulls the product steadily through the line, maintaining consistent speed and shape. Depending on the product, cutting or winding equipment finishes the process by cutting lengths or rolling sheets.

The extruder is the heart of the line. Its job is to melt, mix, and push plastic through the die at a controlled rate. The screw inside the barrel plays a key role, moving the plastic forward while mixing it for uniform temperature and consistency.

There are two main extruder types: single-screw and twin-screw. Single-screw extruders work well for simpler materials like polyethylene and polypropylene. Twin-screw extruders excel at mixing and handling complex materials such as PVC or wood-plastic composites (WPC). They provide better control over melting and blending, which improves product quality.

Extruders also have heating zones along the barrel, each controlled precisely to maintain the right melt temperature. This control prevents overheating or underheating, which can damage the plastic or affect product quality.

Dies shape the molten plastic into the desired profile. They are precision-engineered tools made from hardened metal to withstand high pressure and heat. The die’s design determines the product’s cross-section, whether round pipes, flat sheets, or complex window profiles.

Good die design ensures uniform flow of molten plastic, preventing defects like uneven wall thickness or surface imperfections. For hollow products like pipes, dies often work with calibrators or vacuum systems that help maintain shape during cooling.

Tooling also includes calibrators, cooling tanks, haul-offs, and cutters. Calibrators hold the soft extrudate to exact dimensions until it solidifies. Cooling tanks rapidly cool the product to lock in shape. Haul-offs pull the product steadily, and cutters or winders finish the product for packaging.

Proper tooling is critical for consistent product quality and efficient production. Poorly designed dies or tooling can cause scrap, slow production, or increase maintenance needs.

Tip: Regularly inspect and maintain dies and tooling to prevent wear and ensure consistent product quality throughout production runs.

Extrusion lines come in various types, each designed to create specific kinds of plastic products. The choice depends on the product shape, size, and material. Here’s a detailed look at the main types of extrusion lines:

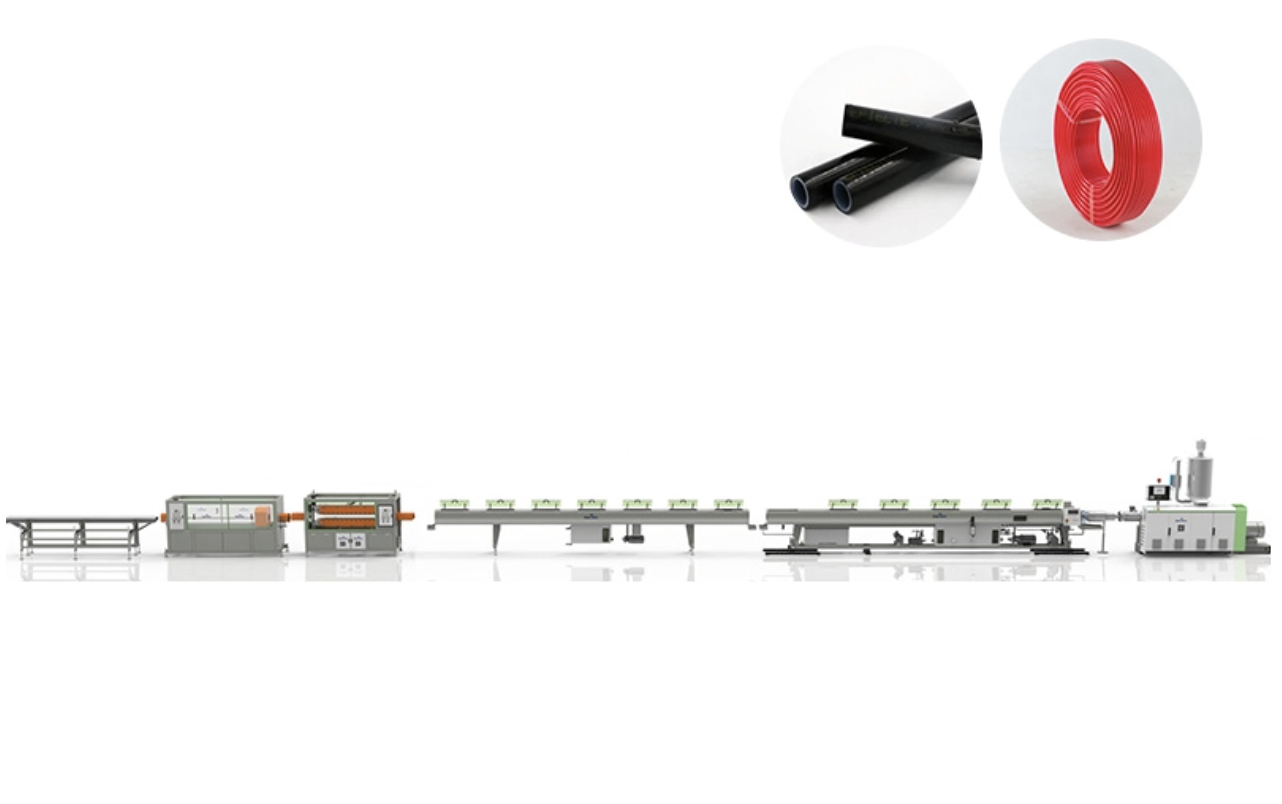

Pipe extrusion lines produce plastic pipes used in plumbing, irrigation, electrical conduits, and more. These lines often use materials like PVC, HDPE, or polypropylene. The process involves pushing molten plastic through a circular die to form a hollow pipe. A vacuum calibrator and cooling tanks keep the pipe’s shape as it cools. Afterward, haul-off units pull the pipe steadily, and cutters trim it to length. Advanced pipe lines can make multi-layer or corrugated pipes, adding strength or flexibility.

Profile extrusion lines create continuous shapes other than pipes, such as window frames, door profiles, and decorative trims. They use custom dies to form complex cross-sections. For example, uPVC profile extrusion lines produce rigid window and door frames with multiple chambers for insulation. These lines include calibrators and cooling tables to maintain shape and size during solidification. They often feature pullers and cutters at the end to finish the product.

Sheet extrusion lines produce flat plastic sheets or films. Materials like polypropylene, polyethylene, or PVC are melted and pushed through a wide, flat die. The molten sheet passes through cooling rollers or calender rolls, which cool and smooth it to precise thickness. Sheets can be wound into rolls or cut into panels. Special sheet lines produce roofing panels or multi-wall sheets used in construction. These lines must maintain uniform thickness and surface quality.

Foam board lines produce lightweight, rigid sheets with a foamed core. These sheets are commonly used in signage, furniture, and construction. The extrusion process mixes plastic with foaming agents to create a cellular structure inside the sheet. Twin-screw extruders are often used for better mixing. The line includes a flat T-die and calibration units to control the sheet’s thickness and cell structure. Cooling is carefully managed to ensure uniform foam expansion.

Wood-Plastic Composite (WPC) extrusion lines process a mix of plastic and wood fibers to create durable, wood-like products. Common items include decking boards, fencing, and profiles. These lines use twin-screw extruders to mix abrasive wood flour with plastic. The downstream equipment resembles profile or board lines with cooling and cutting units. WPC materials retain heat longer, so cooling and haul-off sections are often extended to ensure proper solidification.

Each extrusion line type is tailored to the product’s requirements, ensuring efficient production and consistent quality.

Tip: Choose an extrusion line type based on your product’s shape and material to optimize production efficiency and product quality.

Extrusion lines handle a variety of plastic materials, each chosen for its unique properties and suitability for specific products. Here are the most common plastics processed:

● PVC (Polyvinyl Chloride): Known for rigidity, flame resistance, and affordability. Used in pipes, window frames, siding, and foam boards. Often processed with twin-screw extruders to ensure thorough mixing and temperature control.

● PE (Polyethylene): Includes HDPE and LDPE. HDPE is popular for water pipes, irrigation tubes, and wire insulation due to toughness and chemical resistance. Single-screw extruders commonly process PE for high output.

● PP (Polypropylene): Offers higher temperature resistance than PE. Used in pipes for hot water, automotive profiles, and sheets. Also processed mostly with single-screw extruders.

● WPC (Wood-Plastic Composites): Combines plastic with wood fibers, producing wood-like decking, fencing, and profiles. Requires twin-screw extruders for good mixing and handling abrasive fillers.

● ABS, Polycarbonate, PET, and Others: Used for impact-resistant profiles, sheets, or specialty applications. Some need vented extruders to remove moisture.

Choosing the right material depends on product requirements like strength, flexibility, heat resistance, and cost. The extrusion line must match the material’s processing needs:

● Extruder Type: PVC and WPC often need twin-screw extruders for better mixing and temperature control. PE and PP typically use single-screw extruders.

● Temperature Control: Different plastics melt at different temperatures. Precise heating zones prevent degradation and ensure consistent melt quality.

● Screw and Barrel Design: Materials with fillers or additives may require specialized screws to handle abrasiveness or promote mixing.

● Additives and Recyclates: Some lines can co-extrude multiple materials or incorporate recycled plastics, improving sustainability and cost-efficiency.

Proper material selection and matching extrusion equipment optimize product quality, reduce waste, and improve line efficiency.

Tip: Always verify material compatibility with your extrusion line’s screw design and temperature capabilities to ensure smooth processing and consistent product quality.

Extrusion lines serve many industries by producing a wide range of plastic products. Their ability to create continuous shapes efficiently makes them essential in various manufacturing sectors.

The construction industry relies heavily on extrusion lines for materials like pipes, profiles, and sheets. Plastic pipes from extrusion lines are used in water supply, sewage, gas distribution, and electrical conduits. Profiles made from uPVC offer durable window and door frames, vinyl siding, and cable ducts. Roofing sheets, often made from PVC or polycarbonate, provide weather-resistant coverings for sheds and greenhouses. Foam boards produced by extrusion are lightweight and used as insulation or wall panels. Wood-plastic composite (WPC) decking and fencing also come from specialized extrusion lines, offering weatherproof alternatives to wood.

Extrusion lines produce conduits and ducts that protect electrical wiring and fiber-optic cables. Corrugated tubing and cable trunking are common extruded products in this sector. Extrusion also coats and insulates electrical wires by applying plastic jacketing continuously around copper conductors. This over-jacketing process ensures consistent insulation thickness and protection. The ability to produce customized profiles helps meet the precise needs of electrical and telecommunications applications.

While injection molding and blow molding dominate container production, extrusion plays a key role in packaging films and sheets. Extruded polypropylene or PET sheets are thermoformed into trays, cups, and clamshell packaging. Blown film extrusion lines create plastic bags, stretch wraps, and agricultural films by inflating a molten plastic tube into a thin film bubble. Extruded straws, nets, and profiles also serve packaging and product protection roles. The continuous nature of extrusion allows high-volume, cost-effective production of packaging materials.

Extrusion lines produce many plastic components for vehicles. Weatherstrips, gaskets, and seals made from flexible PVC or thermoplastic elastomers are used in doors and windows. Plastic trim profiles, dashboard parts, and cable protection sleeves come from extrusion lines as well. Tubing for pneumatic or fuel lines is often extruded from nylon or PTFE for durability and chemical resistance. The ability to create custom profiles helps reduce vehicle weight by replacing metal or rubber parts with plastic, improving fuel efficiency.

Many household products come from extrusion lines. Plastic tubing and profiles form parts of appliances, furniture edge bandings, curtain rails, and picture frames. PVC foam boards and sheets are popular in furniture and cabinetry as lightweight, moisture-resistant alternatives to wood. Garden hoses, vinyl flooring, and window blinds are also made using extrusion technology. The versatility of extrusion allows manufacturers to produce durable, attractive consumer goods efficiently.

Tip: When selecting extrusion lines for industrial applications, consider the specific product requirements and material properties to ensure optimal performance and durability in the target sector.

Extrusion lines offer many benefits that make them a top choice for manufacturing plastic products. These advantages help companies produce high-quality items efficiently and cost-effectively.

Extrusion lines run continuously, which means they can produce large volumes of product non-stop. Once set up, the process needs little downtime except for routine maintenance or product changeovers. This steady operation allows manufacturers to meet high demand quickly. For example, a pipe extrusion line can produce hundreds of meters of pipe in a single shift, far faster than batch processes.

Because the process pushes molten plastic through a fixed die, the product’s shape and size stay uniform along its entire length. Modern extrusion lines use sensors and automated controls to keep temperatures, pressures, and line speeds steady. This precision ensures every piece meets quality standards, reducing scrap and rework. Consistent wall thickness, smooth surfaces, and exact dimensions are typical results.

Extrusion lines can make a huge variety of shapes by simply swapping dies and adjusting settings. Whether you need simple round pipes or complex window profiles with multiple chambers, extrusion can handle it. This flexibility means manufacturers can produce custom designs without buying new machines. It also allows quick product changeovers, saving time and money.

Extrusion generates very little waste. Any scrap, like edge trims, can often be reground and reused. The continuous process avoids frequent startup losses seen in batch methods. Plus, extrusion lines can incorporate recycled materials or additives to lower costs. For instance, co-extruding a recycled plastic layer inside a pipe wall reduces material costs while maintaining strength.

Extrusion lines are highly automated. One or two operators can manage an entire line, loading raw materials and monitoring output. Automation features like gravimetric feeders, automatic thickness control, and inline quality sensors reduce human error and labor costs. This also improves safety and consistency, as machines handle the most critical steps.

Tip: Regularly calibrate and maintain your extrusion line’s sensors and controls to sustain high efficiency and consistent product quality over time.

Selecting the right extrusion line is crucial for efficient production and high-quality output. Several key factors influence this decision, ensuring the line matches your product needs and business goals.

Start by defining the exact product you want to make. The shape—pipe, profile, sheet, or foam board—and size determine the extrusion line type. For example, making hollow window frames requires a profile line with vacuum calibration. Flat panels call for a sheet or foam board line. Ensure the line can handle your product’s largest dimensions and complexity. Custom shapes or multi-layer products may need specialized dies or co-extrusion capabilities.

Different plastics need different extrusion setups. PVC often uses twin-screw extruders for better mixing and heat control, while PE and PP usually run on single-screw extruders. If you plan to use composites like wood-plastic composites (WPC) or recycled materials, choose a line with appropriate screw designs and features like venting to remove moisture. Matching the extruder and screw to the material prevents problems like poor melt quality or excessive wear.

Consider how much product you need to produce daily or hourly. Larger extruders with bigger screws and motors offer higher throughput but consume more energy and cost more upfront. It’s wise to select a line that meets current demand but allows some growth. Modular or upgradable lines can help scale production without full replacement.

Tight tolerances and smooth surface finishes require advanced control systems. Features like automatic thickness control using laser or ultrasonic sensors help maintain consistent dimensions. Cooling and calibration systems must be adequate to prevent warping or defects, especially for complex profiles. Investing in high-quality screws, barrels, and tooling improves repeatability and reduces scrap.

Extrusion lines run continuously, so energy use impacts operating costs significantly. Look for lines with energy-saving motors, efficient heaters, and smart drive controls. Durable components reduce maintenance frequency and downtime. Quick-change tooling and easy-clean features also lower labor costs. Balancing initial investment and long-term operating expenses is key for profitability.

Tip: When choosing an extrusion line, prioritize compatibility between your product design, material, and production volume to ensure smooth operation and cost-effective manufacturing.

Extrusion lines efficiently produce plastic products with high consistency and versatility. They handle various materials, offering benefits like high throughput and low waste. As technology advances, extrusion lines will become even more efficient and adaptable, meeting diverse industrial needs. Foshan Bkwell Machinery Co., Ltd. provides state-of-the-art extrusion solutions, ensuring optimal performance and quality. Their innovative designs cater to specific customer requirements, delivering reliable and cost-effective production capabilities.

A: An extrusion machine is used to melt and shape raw plastic material into continuous profiles like pipes, sheets, and tubes by pushing it through a die.

A: An extrusion machine works by heating plastic pellets until molten, then forcing them through a die to form continuous shapes, which are cooled and solidified.

A: Extrusion machines are efficient because they operate continuously, producing large quantities of uniform products with minimal waste.

A: Benefits include high efficiency, consistent product quality, versatility in shapes, material cost savings, and reduced labor requirements due to automation.

A: Troubleshoot by checking for blockages, calibrating sensors, maintaining temperature controls, and ensuring synchronized speeds between components.