Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

As global demand for high-quality, customizable plastic products increases, manufacturers are looking for advanced solutions to enhance productivity, consistency, and sustainability in their operations. Sheet extrusion is one of the most effective methods to optimize your plastic extrusion process, enabling you to produce high-volume, precise plastic sheets for packaging, automotive interiors, building materials, medical trays, and more.

This article will explore how sheet extrusion can transform your plastic extrusion operations, the advantages it offers, the latest technological advancements, and how Foshan Bkwell Intelligent Equipment Co., Ltd. can support you with state-of-the-art extrusion lines to elevate your production efficiency.

Sheet extrusion is a vital continuous manufacturing process in the plastics industry, designed to produce flat plastic sheets with uniform thickness and high-quality surface finishes. The process begins with feeding raw thermoplastic pellets into the extruder, where they are melted and homogenized through the screw and barrel system. This ensures a consistent and uniform melt flow, which is then forced through a flat die to form the sheet. The emerging sheet is carefully calendered and cooled on a Three roller calinder Hollow tubes, which not only controls the final thickness but also imparts a smooth surface finish. After cooling, the sheet is either cut into specific sizes or wound onto rolls for further processing or downstream applications.

This method is essential for creating plastic sheets with tight thickness tolerances, high surface quality, and excellent mechanical properties. These characteristics make sheet extrusion an integral part of plastic manufacturing, particularly for applications that demand precision and reliability, such as packaging, automotive components, and medical devices. The ability to control the thickness and surface finish precisely allows manufacturers to produce high-quality sheets that meet the specific requirements of various industries, ensuring durability, functionality, and aesthetic appeal in the final products.

Sheet extrusion lines, especially those equipped with advanced PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) controls, offer unparalleled precision in managing critical process parameters. These controls enable operators to meticulously regulate temperature, pressure, and material throughput, ensuring that each sheet produced maintains consistent thickness and surface finish throughout the entire production run. This level of consistency is crucial for applications where uniformity is paramount, such as in medical devices, automotive components, and high-end packaging. The ability to maintain tight tolerances reduces the likelihood of defects, thereby enhancing product reliability and customer satisfaction.

One of the most significant advantages of sheet extrusion is its continuous operation capability. Unlike batch processing methods, which involve frequent stops and starts, sheet extrusion lines can run uninterrupted for extended periods. This continuous operation not only increases output rates but also significantly reduces downtime, leading to higher overall production efficiency. The ability to produce large quantities of sheets in a single run minimizes the need for frequent setups and adjustments, further streamlining the manufacturing process and reducing production costs.

Sheet extrusion is highly versatile, capable of processing a wide range of thermoplastic materials. This versatility is a major asset for manufacturers, as it allows them to produce sheets from various materials to meet specific application requirements. Common materials used in sheet extrusion include:

PET (Polyethylene Terephthalate) and PETG (Polyethylene Terephthalate Glycol): Known for their clarity, strength, and recyclability, these materials are ideal for food and beverage packaging, as well as medical applications.

PVC (Polyvinyl Chloride): Offers excellent flexibility and chemical resistance, making it suitable for applications such as medical trays and construction materials.

PP (Polypropylene) and PE (Polyethylene): These materials are lightweight and durable, commonly used in packaging and automotive components.

PC (Polycarbonate), PS (Polystyrene), and ABS (Acrylonitrile Butadiene Styrene): Known for their impact resistance and ease of processing, these materials are used in a variety of applications, including automotive panels and consumer electronics.

PLA (Polylactic Acid) and other biodegradable polymers: These materials are environmentally friendly and suitable for applications where sustainability is a key consideration, such as single-use packaging and disposable medical devices.

This wide range of materials enables manufacturers to tailor their products to meet the specific needs of various industries, from food and beverage to automotive and medical sectors.

Sheet extrusion is a cost-effective manufacturing method that minimizes material waste and offers several advantages in terms of production efficiency. The continuous nature of the process reduces the need for frequent setups and adjustments, thereby lowering labor costs. Additionally, sheet extrusion lines can be easily integrated with inline recycling systems, allowing manufacturers to reuse scrap material and further reduce waste. The ability to incorporate inline processes such as lamination, printing, or embossing directly into the production line eliminates the need for secondary processing steps, reducing overall production costs and lead times. These cost-saving benefits make sheet extrusion an attractive option for manufacturers looking to optimize their production processes and improve profitability.

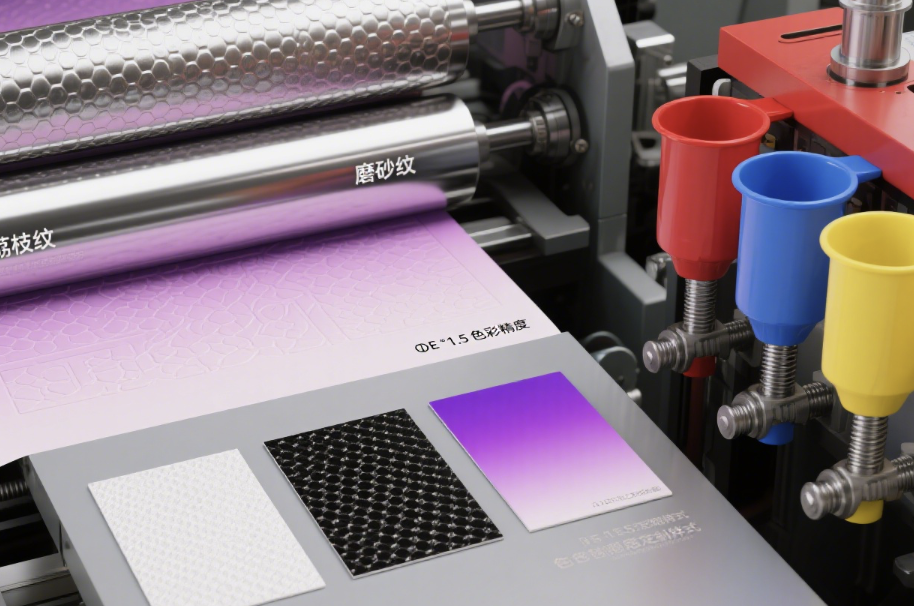

Sheet extrusion offers a high degree of customization, allowing manufacturers to adjust sheet thickness, width, surface texture, and color to meet specific customer requirements. This flexibility is crucial in today’s competitive market, where customers often demand tailored solutions. Extrusion lines can be easily reconfigured to produce sheets with different dimensions and properties, ensuring that manufacturers can quickly adapt to changing market demands. Furthermore, sheet extrusion lines are scalable, meaning they can be expanded to accommodate increasing production volumes without compromising the quality of the final product. This scalability ensures that manufacturers can grow their operations while maintaining consistent product quality, making sheet extrusion a future-proof manufacturing solution.

While extrusion is used in various forms like tubing, profile, and blown film extrusion, sheet extrusion offers unique advantages in producing flat, high-precision sheets.

Table: Comparison of Sheet Extrusion with Other Extrusion Processes

| Feature | Sheet Extrusion | Tubing Extrusion | Blown Film Extrusion |

|---|---|---|---|

| Product Form | Flat sheets | Hollow tubes and profiles | Thin film rolls |

| Thickness Control | Tight control (±1-3%) | Micron-level ID/OD control | Varies with blow-up ratio |

| Surface Quality | High surface finish | Moderate surface finish | Varies with material and cooling |

| Production Speed | Moderate to high | Low to moderate for precision | High |

| Applications | Packaging, automotive, building | Catheters, straws, cables | Bags, wraps, packaging films |

Sheet extrusion allows manufacturers to achieve high-volume, precise production for flat sheet products, making it the preferred method for industries requiring consistent thickness and surface properties.

An efficient sheet extrusion line typically includes:

Feeding System: Gravimetric feeders for accurate material dosing.

Extruder: Single or twin-screw extruders designed for material-specific requirements.

Screen Changer and Melt Pump: For maintaining melt cleanliness and pressure stability.

Flat Die: Distributes the melt uniformly across the width.

Three-Roll Calender Stack: Cools, smooths, and determines the final thickness.

Haul-Off Unit: Pulls the sheet through the process at a consistent speed.

Edge Trimmers and Winder or Cutter: Finalizes sheet dimensions and prepares for storage or further processing.

Bkwell’s extrusion lines offer advanced modular configurations, enabling you to add co-extrusion layers, embossing units, or lamination systems to meet specific application needs.

For consistent, high-quality sheet extrusion, monitoring and controlling critical parameters are essential.

Melt Temperature: Stable temperature prevents degradation and ensures homogeneity.

Melt Pressure: Consistent pressure ensures uniform flow through the die.

Throughput: Controlled feeding and extruder speed optimize output rates.

Die Lip Adjustment: Allows fine-tuning of thickness across the sheet width.

Calender Roll Temperature and Pressure: Critical for surface finish and thickness accuracy.

Line Speed: Coordinated with cooling and pulling systems to maintain stability.

Bkwell’s extrusion lines utilize advanced PLC-based control systems, enabling operators to monitor these parameters in real-time, adjust settings efficiently, and store recipes for repeatable production quality.

While sheet extrusion offers numerous benefits, manufacturers may face several challenges that can impact product quality, efficiency, and overall production costs. However, with the right solutions and modern technologies, these challenges can be effectively addressed.

One common challenge in sheet extrusion is achieving consistent thickness across the entire width of the sheet. Variations in thickness can lead to uneven performance and quality issues in the final product. To address this, advanced flat dies equipped with manual or automatic die lip adjustments can be used. These adjustments allow for precise control over the melt flow, ensuring uniform thickness. Additionally, incorporating thickness monitoring systems can provide real-time feedback, enabling operators to make necessary adjustments during production. This combination of advanced die technology and monitoring systems helps maintain consistent sheet thickness throughout the production run.

Material degradation and gel formation are critical issues that can affect the quality and appearance of the extruded sheets. Degradation often occurs due to excessive heat or poor melt homogeneity, leading to defects such as gels or black specks. To mitigate this, precise melt temperature control is essential. Multi-zone heating systems allow for fine-tuned temperature management along the extruder barrel, ensuring that the material is processed at the optimal temperature. Coupled with an efficient screw design that promotes uniform melt flow, this approach helps prevent degradation and ensures a homogeneous melt. Regular maintenance and calibration of the extrusion equipment also play a crucial role in maintaining consistent processing conditions.

Surface defects, such as streaks, lines, or uneven textures, can significantly impact the aesthetic and functional quality of the extruded sheets. These defects often arise from impurities in the melt flow or improper calender roll settings. To address this, maintaining clean melt flow paths is essential. This includes regular cleaning of the extruder and die to prevent contamination. Additionally, using filtration systems can help remove impurities and ensure a clean melt. Optimizing calender roll temperatures and pressures is also crucial for achieving a smooth and defect-free surface finish. By carefully managing these parameters, manufacturers can produce high-quality sheets with excellent surface characteristics.

Waste management is another significant challenge in sheet extrusion, as excess material and scrap can lead to increased costs and environmental concerns. To minimize waste, manufacturers can implement inline edge trim recycling systems. These systems capture and reprocess excess material directly on the production line, reducing waste and improving sustainability. Additionally, optimizing the extrusion process to minimize scrap generation and incorporating efficient reprocessing methods can further enhance waste management efforts. By adopting these practices, manufacturers can reduce material waste and lower production costs while contributing to a more sustainable manufacturing process.

High energy consumption is a common concern in the extrusion process, as it can significantly impact operational costs. To address this, manufacturers can adopt energy-efficient heating systems that use advanced insulation and heat recovery techniques. These systems ensure that energy is used efficiently, reducing overall energy consumption. Additionally, advanced control systems can optimize the extrusion process, ensuring that energy is used only when necessary. By combining energy-efficient heating with smart control systems, manufacturers can achieve significant energy savings without compromising product quality.

Sheet extrusion is a continuous manufacturing process used to produce flat plastic sheets with uniform thickness and high-quality surface finishes. It involves melting thermoplastic pellets and forming them into sheets through a flat die, followed by cooling and calendering.

The continuous operation of sheet extrusion lines allows for high output rates and reduced downtime compared to batch processing methods. This streamlines the manufacturing process, lowers production costs, and increases overall efficiency.

Sheet extrusion minimizes material waste through inline recycling systems and reduces the need for secondary processing steps by integrating processes like lamination, printing, or embossing directly into the production line. This lowers overall production costs and lead times.

Yes, sheet extrusion offers a high degree of customization, allowing adjustments in sheet thickness, width, surface texture, and color to meet customer requirements. Extrusion lines are also scalable, enabling manufacturers to increase production volumes without compromising quality.

Sheet extrusion is a critical process for optimizing your plastic extrusion operations, offering precision, consistency, and high productivity for a wide range of applications.With the support of advanced extrusion lines from Foshan Bkwell Intelligent Equipment Co., Ltd., you can expand your capabilities to include multi-layer and specialty sheet production. If you are ready to optimize your plastic extrusion process through advanced sheet extrusion technology, Bkwell can deliver the expertise, equipment, and support to help you succeed.