Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

Medical tubing extrusion is a highly specialized segment within the plastic extrusion industry that demands precision, cleanliness, and consistency. As the medical device sector rapidly grows, so does the need for high-quality medical tubing in applications such as IV lines, catheter tubing, drug delivery systems, and surgical drains.

This article will explore the process characteristics of medical tubing extrusion, the relationship with sheet extrusion and extrusion lines, the latest technological advancements, quality control considerations, and how manufacturers like Foshan Bkwell Intelligent Equipment Co., Ltd. can support your needs with reliable, advanced extrusion solutions.

Medical tubing extrusion involves the continuous process of forming thermoplastic polymers into hollow profiles with tight dimensional tolerances, high surface quality, and biocompatibility.

1.Precision Control:

Wall thickness and inner/outer diameters must be consistently controlled within microns.

Use of gravimetric feeders for consistent material throughput.

Advanced closed-loop control systems linked with laser or ultrasonic measurement tools during production.

2.Material Purity and Compatibility:

Uses medical-grade polymers such as PVC, TPU, TPE, PEEK, PE, PP, and silicone.

Must meet ISO 10993, USP Class VI, and FDA guidelines.

3.Cleanroom Manufacturing:

Many tubing extrusion lines are installed in Class 100,000 or higher cleanrooms to prevent contamination.

Positive pressure environments and HEPA filtration.

4.Multi-Lumen and Co-Extrusion Capability:

Ability to extrude multi-lumen tubes for complex catheter designs.

Co-extrusion for adding radiopaque stripes or colored layers.

5.Post-Extrusion Processing:

Inline annealing, cutting, laser marking, and coiling.

Inline quality monitoring for defects.

While medical tubing extrusion differs in geometry from sheet extrusion, the core principles of extrusion lines remain aligned:

Both require stable temperature control across the barrel and die.Both use precision screw and barrel design to ensure consistent melt homogeneity.Extrusion lines for sheet extrusion and tubing often share similar PLC and HMI control architectures, with Bkwell’s systems providing user-friendly, modular interfaces for recipe management and traceability. Material drying and handling systems are similar, especially for hygroscopic materials like TPU or PETG.

Table: Comparison Between Medical Tubing Extrusion and Sheet Extrusion

| Feature | Medical Tubing Extrusion | Sheet Extrusion |

|---|---|---|

| Geometry | Hollow cylindrical or multi-lumen | Flat continuous sheets |

| Tolerance | Micron-level ID/OD control | Thickness control within 1-3% |

| Material Focus | Medical-grade PVC, TPU, PEEK | PETG, PVC, PP, PS, PC |

| Cleanroom Use | Often required | Rarely required |

| Inline Monitoring | Laser/ultrasonic for diameter | Thickness gauges (beta-ray, laser) |

| Applications | IV lines, catheters, drug delivery | Blister packs, thermoformed trays, partitions |

| Extrusion Speed | Moderate to low for precision | Moderate to high for productivity |

Bkwell’s extrusion lines can be customized for both applications, enabling manufacturers to achieve stable, high-output, and clean production environments for medical product manufacturing.

As medical device regulations become increasingly stringent, the demand for batch traceability has never been higher. Modern extrusion lines are now equipped with advanced technologies to meet these requirements. RFID tagging and QR coding are integrated at the spool level, allowing for seamless tracking of each batch throughout the production process. Inline monitoring systems with automatic SPC (Statistical Process Control) data logging ensure that every aspect of the extrusion process is meticulously recorded and analyzed in real-time.

Perhaps most intriguingly, AI-based process adjustment has revolutionized the industry by enabling the extrusion lines to automatically optimize dimensional control and minimize scrap. This not only enhances product quality but also significantly reduces material waste and production costs, making the manufacturing process more efficient and sustainable.

The advent of micro-extrusion has opened up new possibilities in the medical device industry, particularly for minimally invasive surgical devices and microcatheters. This technology allows for the production of tubing with outer diameters (ODs) as small as 0.2mm, which is crucial for applications where precision and minimal invasiveness are paramount. Achieving such small dimensions requires specialized equipment and techniques.

High L/D (length-to-diameter) ratio screws are essential for ensuring consistent melt quality, while specialized die designs help reduce die swell and maintain the desired tubing shape. Precision pullers and cutters are also critical, as they must handle the delicate tubing without causing deformation. These advancements in micro-extrusion have enabled manufacturers to push the boundaries of what is possible in medical device design and functionality.

The medical tubing industry is witnessing a growing demand for high-performance polymers such as PEEK (Polyether Ether Ketone) and FEP (Fluorinated Ethylene Propylene). These materials are highly valued for their exceptional chemical resistance and compatibility with steam sterilization processes, making them ideal for use in medical devices that require rigorous cleaning and disinfection. However, working with these advanced materials presents its own set of challenges.

Higher processing temperatures are necessary to achieve the desired melt flow properties, which in turn necessitates the use of corrosion-resistant barrels and screws to withstand the harsh conditions. Additionally, advanced thermal stability and pressure control systems are crucial to ensure consistent extrusion quality and prevent material degradation. By overcoming these challenges, manufacturers can leverage the superior properties of these materials to create medical tubing that meets the highest standards of performance and reliability.

In an effort to streamline production and enhance efficiency, modern tubing extrusion lines are now integrating inline ultrasonic cutting and laser marking technologies. Ultrasonic cutters offer a significant advantage over traditional cutting methods, as they are able to cut tubing without causing deformation or damage. This precision is crucial for maintaining the integrity of the tubing, especially for applications where dimensional accuracy is critical.

Laser markers, on the other hand, provide a highly efficient and precise means of adding lot numbers, length markers, or customer-specific codes directly onto the tubing. This not only improves traceability but also enhances the overall quality and customization of the final product. By incorporating these inline processes, manufacturers can reduce production time, minimize human error, and ensure consistent product quality throughout the entire manufacturing cycle.

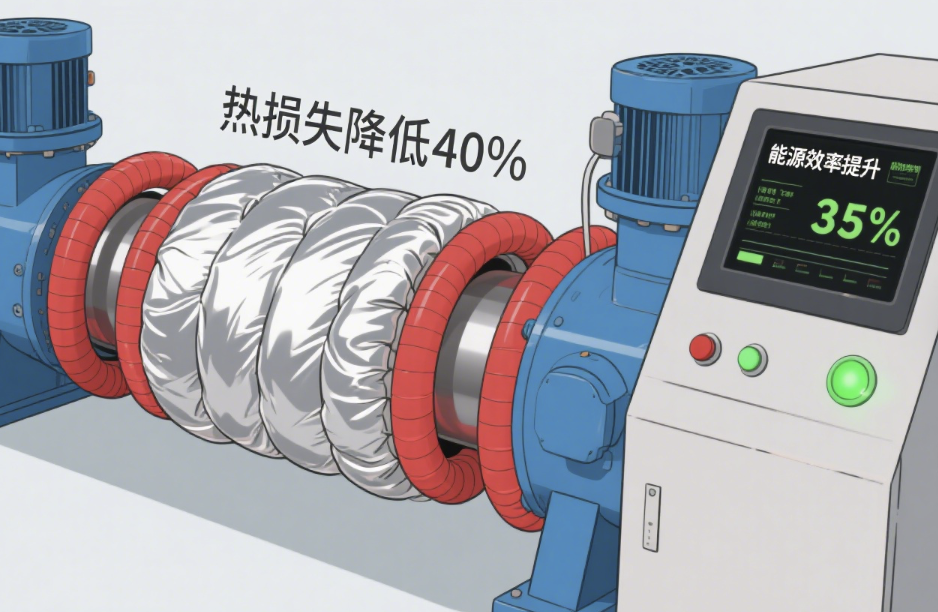

With sustainability becoming an increasingly important consideration in medical production, extrusion lines are evolving to incorporate eco-friendly practices. One key trend is the use of recyclable or bio-based polymers, which offer a more sustainable alternative to traditional materials without compromising on performance. Additionally, energy-saving barrel heating systems are being implemented to reduce the overall energy consumption of the extrusion process. These systems utilize advanced insulation and heat recovery techniques to optimize energy efficiency.

Furthermore, precise start-stop control mechanisms are being developed to minimize waste during production. By reducing material waste and lowering energy consumption, these sustainability-focused advancements not only benefit the environment but also contribute to cost savings for manufacturers. As the industry continues to prioritize sustainability, we can expect to see even more innovative solutions emerge in the realm of medical tubing extrusion.

Foshan Bkwell Intelligent Equipment Co., Ltd. offers a comprehensive range of extrusion lines designed for both medical tubing extrusion and sheet extrusion, supporting:

Custom die and screw design for different polymer types.

Automated control systems for real-time monitoring and adjustment.

Energy-efficient heating systems to reduce operational costs.

Modular configurations that allow the addition of co-extrusion heads, laser measurement systems, and inline cutting/marking units.

Complete downstream equipment including pullers, cutters, winders, and coilers optimized for medical applications.

If you aim to diversify your extrusion production, Bkwell’s expertise in sheet extrusion technology complements medical tubing extrusion through:

Shared maintenance and operational procedures.

Similar control systems reducing operator learning curves.

Unified spare parts management.

Medical tubing extrusion is a specialized process of forming thermoplastic polymers into hollow profiles with tight dimensional tolerances, high surface quality, and biocompatibility for use in medical applications such as IV lines, catheter tubing, drug delivery systems, and surgical drains.

Precision is crucial in medical tubing extrusion to ensure consistent wall thickness and accurate inner/outer diameters within microns, which is necessary for proper functionality and safety in medical devices.

Wall thickness and inner/outer diameters are controlled using gravimetric feeders for consistent material throughput and advanced closed-loop control systems linked with laser or ultrasonic measurement tools during production.

Micro-extrusion allows the production of tubing with outer diameters as small as 0.2mm, which is essential for minimally invasive surgical devices and microcatheters. It requires specialized equipment to ensure consistent melt and precise shaping.

Benefits include tailored solutions for medical tubing, integrated quality control systems, sustainable and energy-efficient extrusion lines, and the ability to diversify production while maintaining operational efficiency and regulatory compliance.

The medical tubing extrusion process is a critical, precision-driven manufacturing segment that requires robust control, specialized materials, and advanced technology to ensure consistency and regulatory compliance. By investing in advanced medical tubing extrusion lines, you can meet the rising demand for high-quality medical devices while maintaining operational efficiency and regulatory compliance.

Want to learn how Bkwell’s extrusion lines can transform your medical tubing or sheet extrusion production? Contact us to discuss your project and get a customized solution that fits your goals.