Views: 0 Author: Site Editor Publish Time: 2025-06-06 Origin: Site

Film extrusion is a pivotal process in the plastics industry, enabling the production of thin plastic films used across various sectors, including packaging, agriculture, and medical applications. Foshan Bkwell Intelligent Equipment Co., Ltd. specializes in manufacturing advanced film extrusion machinery, catering to the evolving demands of the global market.

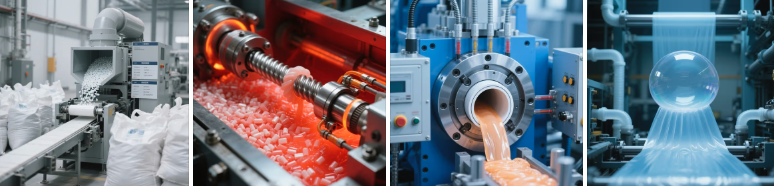

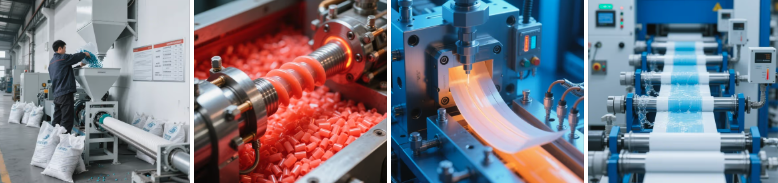

Film extrusion involves melting plastic resins and forming them into continuous thin films. The two primary methods are blown film extrusion and cast film extrusion. Each technique has distinct processes, advantages, and applications.

Blown film extrusion is widely used for producing films with balanced mechanical properties. The process includes:

Material Feeding: Plastic pellets are fed into an extruder.

Melting: The pellets are heated and melted into a homogeneous molten state.

Extrusion Through Die: The molten plastic is extruded through a circular die to form a thin-walled tube.

Inflation: Air is introduced to inflate the tube into a bubble, stretching the film both longitudinally and transversely.

Cooling: The inflated bubble is cooled using air rings or other cooling systems.

Collapsing: The cooled bubble is collapsed into flat film through nip rollers.

Winding: The flattened film is wound onto rolls for further processing or packaging.

Cast film extrusion is known for producing films with excellent clarity and uniform thickness. The process involves:

Material Feeding: Plastic pellets are fed into an extruder.

Melting: The pellets are melted into a uniform molten state.

Extrusion Through Flat Die: The molten plastic is extruded through a flat die to form a thin sheet.

Quenching: The extruded sheet is rapidly cooled on chilled rollers, solidifying the film.

Winding: The cooled film is wound onto rolls for subsequent use.

| Feature | Blown Film Extrusion | Cast Film Extrusion |

|---|---|---|

| Cooling Method | Air cooling | Chilled rollers |

| Film Clarity | Moderate | High |

| Thickness Uniformity | Less uniform | Highly uniform |

| Mechanical Properties | Balanced strength | High clarity, less toughness |

| Production Speed | Slower | Faster |

| Applications | Grocery bags, agricultural films | Food packaging, medical films |

Blown film extrusion and cast film extrusion are two primary methods used in the production of plastic films, each with distinct characteristics and applications. Blown film extrusion uses air cooling to solidify the film, resulting in moderate clarity and less uniform thickness. This method is known for producing films with balanced mechanical properties and is commonly used for applications such as grocery bags and agricultural films. Due to the nature of the process, production speeds are generally slower.

On the other hand, cast film extrusion utilizes chilled rollers for cooling, which results in films with high clarity and highly uniform thickness. This method tends to produce films with less toughness but is ideal for applications requiring high clarity, such as food packaging and medical films. Cast film extrusion also allows for faster production speeds, making it more efficient for high-volume production runs.

Choosing between blown and cast film extrusion depends on the specific requirements of the application, including desired film properties, production speed, and cost considerations. Foshan Bkwell Intelligent Equipment Co., Ltd. offers advanced machinery for both processes, ensuring high-quality output tailored to meet the needs of various industries.

Various polymers are utilized in film extrusion, each offering specific properties:

| Material | Properties | Common Applications |

|---|---|---|

| LDPE | Flexibility, clarity | Packaging films, bags |

| HDPE | Strength, opacity | Grocery bags, liners |

| PP | Clarity, stiffness | Food packaging, textiles |

| EVOH | Gas barrier | Food packaging |

| PA | Strength, barrier | Vacuum packaging |

In film extrusion, a variety of materials are used to achieve specific properties and meet the requirements of different applications. Low-density polyethylene (LDPE) is valued for its flexibility and clarity, making it ideal for packaging films and bags. High-density polyethylene (HDPE) offers greater strength and opacity, commonly used for grocery bags and liners. Polypropylene (PP) provides clarity and stiffness, suitable for food packaging and textiles. Ethylene-vinyl alcohol (EVOH) excels in gas barrier properties, making it a preferred choice for food packaging to maintain freshness. Polyamide (PA) is known for its high strength and barrier properties, often used in vacuum packaging to protect perishable goods. Each material is selected based on the desired characteristics and end-use application, ensuring optimal performance and functionality.

The film extrusion industry is experiencing significant advancements:

Multilayer Films: Combining different polymers to enhance barrier properties and functionality.

Automation: Implementing advanced control systems for precision and efficiency.

Sustainability: Using biodegradable and recycled materials to reduce environmental impact.

Digital Integration: Incorporating IoT and AI for real-time monitoring and predictive maintenance.

Multilayer films represent a significant innovation in the film extrusion industry. By combining different polymers, manufacturers can create films with enhanced barrier properties, UV resistance, and anti-fogging capabilities. This technology is particularly valuable in food packaging, where maintaining product freshness and safety is critical. Foshan Bkwell’s advanced extrusion lines are capable of producing multi-layer films with precise control over layer thickness and composition, ensuring consistent quality and performance.

Automation and digital integration are transforming the film extrusion process. Advanced control systems and IoT capabilities allow for real-time monitoring and adjustment of the extrusion process, ensuring consistent product quality and reducing waste. Predictive maintenance systems use data analytics to identify potential issues before they become critical, minimizing downtime and improving overall efficiency. Foshan Bkwell’s intelligent equipment features automated controls, real-time monitoring, and predictive maintenance, setting new standards for precision and efficiency in film extrusion.

Sustainability is a growing concern in the plastics industry, and film extrusion is no exception. Foshan Bkwell is committed to developing sustainable solutions that reduce environmental impact. Their advanced machinery uses energy-efficient systems and processes that minimize waste and maximize material utilization. Additionally, Foshan Bkwell supports the use of biodegradable and recycled materials, contributing to a circular economy and reducing the carbon footprint of film production.

Extruded films serve diverse industries:

Packaging: Food, pharmaceuticals, consumer goods.

Agriculture: Mulch films, greenhouse covers.

Medical: Sterile packaging, IV bags.

Industrial: Liners, protective films.

In the packaging industry, extruded films are essential for protecting and preserving products. Films made from materials like LDPE and HDPE are commonly used for grocery bags, food packaging, and consumer goods. These films offer excellent barrier properties, protecting products from moisture, gases, and physical damage. Foshan Bkwell’s advanced extrusion machinery ensures that these films meet the highest standards of quality and performance, providing reliable protection for a wide range of products.

In agriculture, extruded films are used for mulch films and greenhouse covers. These films provide protection against environmental factors, improve crop yield, and reduce the need for pesticides. Foshan Bkwell’s advanced extrusion lines produce films with excellent durability and UV resistance, ensuring long-lasting performance in agricultural applications.

The medical industry relies on extruded films for sterile packaging and IV bags. These films must meet stringent regulatory standards to ensure patient safety and product integrity. Foshan Bkwell’s advanced machinery produces films with high clarity and uniform thickness, providing reliable protection for medical products. Their commitment to quality and precision ensures that these films meet the highest standards of performance and reliability.

In industrial settings, extruded films are used for liners and protective films. These films provide protection against chemicals, moisture, and physical damage, ensuring the longevity and performance of industrial products. Foshan Bkwell’s advanced extrusion machinery produces films with high strength and durability, making them suitable for demanding industrial applications.

Foshan Bkwell Intelligent Equipment Co., Ltd. offers a range of film extrusion machinery, including:

Sheet/Plate/Film Extrusion Machines: Designed for high efficiency and precision.

Customization: Tailoring equipment to meet specific production requirements.

Global Reach: Serving clients across Southeast Asia and beyond.

Foshan Bkwell’s advanced film extrusion machinery is designed to meet the highest standards of quality and performance. Their equipment features advanced control systems, real-time monitoring, and predictive maintenance, ensuring consistent product quality and reducing downtime. Foshan Bkwell’s commitment to innovation and precision ensures that their machinery remains at the forefront of industry trends, providing reliable solutions for film extrusion.

Understanding that each industry has unique requirements, Foshan Bkwell offers customized solutions to meet the specific needs of their clients. Whether it’s adjusting film thickness, width, or material composition, Foshan Bkwell’s advanced machinery can produce films tailored to meet the exact specifications of each application. This level of customization ensures that each film meets the highest standards of performance and functionality.

Foshan Bkwell’s global reach ensures that clients across Southeast Asia and beyond have access to their advanced film extrusion machinery. Their commitment to customer satisfaction and quality ensures that clients receive reliable and efficient solutions for their film extrusion needs. By leveraging the latest technologies and sustainable practices, Foshan Bkwell is driving the future of film extrusion and setting new standards for quality, efficiency, and environmental responsibility.

Q1: What is the difference between blown and cast film extrusion?

A1: Blown film extrusion inflates molten plastic into a bubble, producing films with balanced strength. Cast film extrusion spreads molten plastic onto chilled rollers, resulting in films with superior clarity and uniform thickness.([oliverhcp.com][4])

Q2: Which materials are commonly used in film extrusion?

A2: Common materials include LDPE, HDPE, PP, EVOH, and PA, each selected based on desired film properties and applications.

Q3: How does multilayer film extrusion benefit packaging?

A3: Multilayer films combine different polymers to enhance barrier properties, strength, and functionality, making them ideal for specialized packaging needs.

Q4: What advancements are shaping the future of film extrusion?

A4: Innovations include automation, sustainable materials, digital integration, and the development of multilayer films to meet evolving industry demands.

Film extrusion is a dynamic process integral to various industries. Understanding the nuances of blown and cast film extrusion enables manufacturers to select the appropriate method for their specific applications. Foshan Bkwell Intelligent Equipment Co., Ltd. stands at the forefront of this industry, providing advanced, customizable extrusion machinery to meet global demands. By leveraging the latest technologies and sustainable practices, Foshan Bkwell is driving the future of film extrusion and setting new standards for quality, efficiency, and environmental responsibility.